Jordan Brand’s Retro Remaster initiative is not just about using premium materials. It’s about refining the art of traditional shoe-making in a day and age when innovative (and more cost effective) materials and construction methods have become the norm in the footwear business. Knowing that their consumers are passionate and well educated about the sneakers they love, Jordan has answered the call for a higher grade of materials on their Retro releases, but their efforts reach far beyond just using better leathers.

Starting with the Spring 2015 season that will begin in January, all Air Jordan Retros will be crafted using a completely revamped construction process with an elaborate and intimate approach to the way these shoes are manufactured. Aside from just creating a more premium product, the idea is to refine the Retros to be as close as possible to the OGs in every way, from the way they look and feel, to the way they perform and respond to wear. Using original pairs to get each detail true to form, JB is setting out to recreate Tinker and Michael’s original vision for what these shoes should be.

Like the man on the Jumpman logo, his brand is always looking to get better. Being on top is no excuse for complacency and JB is committed to pushing themselves to continue to raise the bar. Last night, Jordan Brand invited a small group of media members to come see the results for ourselves as they unveiled the first batch of Remastered models, walked us through the process and goals of the new approach to Retro manufacturing, and unleashed the bombshell that the recently released “Sport Blue” Air Jordan III was the last colorway of the III that we’ll see for awhile as the brand plans to shelve the model the foreseeable future.

Jordan Brand’s VP Category Footwear Lead, David Schechter, Footwear Engineering Director, Michael Hochdoerffer, and Footwear Product Line Manager, Jeff Atienza walked us through the ins and outs of the remastering process from the conceptual goals to the final product. Continue on for a crash course on the Jordan Retro Remaster initiative where we’ll relay some of the key elements detailed during last night’s info session and give you some insight into the process, as well as a look at the upcoming colorways that are on their way to us next year.

THE PROCESS

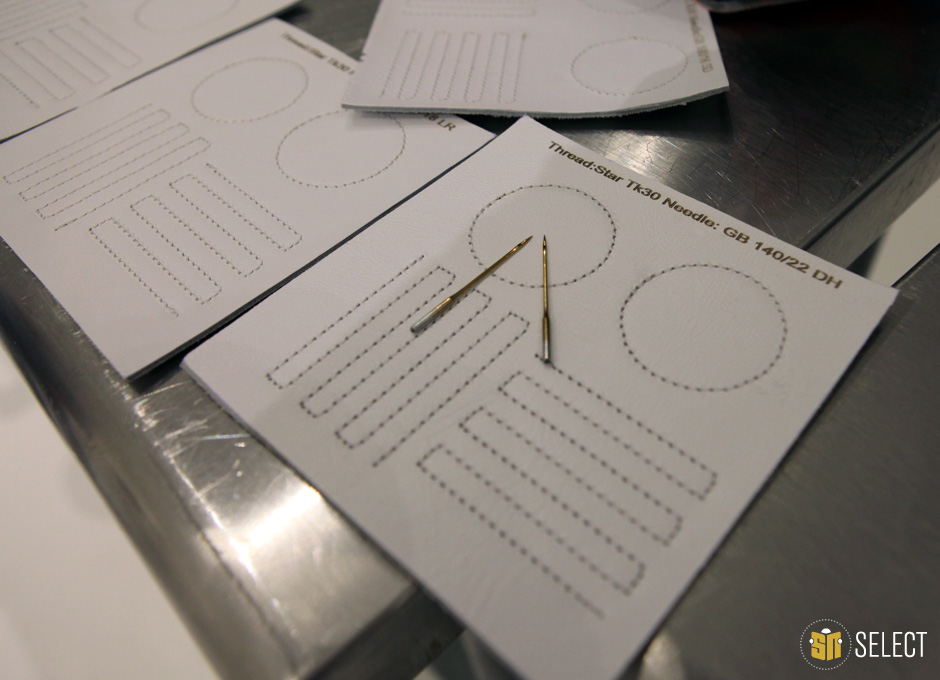

Every pair produced under the Retro Remaster regime will pass through over 100 sets of hands before it gets boxed up and unleashed to eager sneaker consumers at retail. As the shoes go from one step of the intricate process to the next, each person that handles them wears white cotton gloves to keep the product as pristine as possible. Whether it’s cutting materials, lining up edges, or molding the shape, everything has to be absolutely perfect before it can get the green light to move on to the next stage of production.

MATERIALS

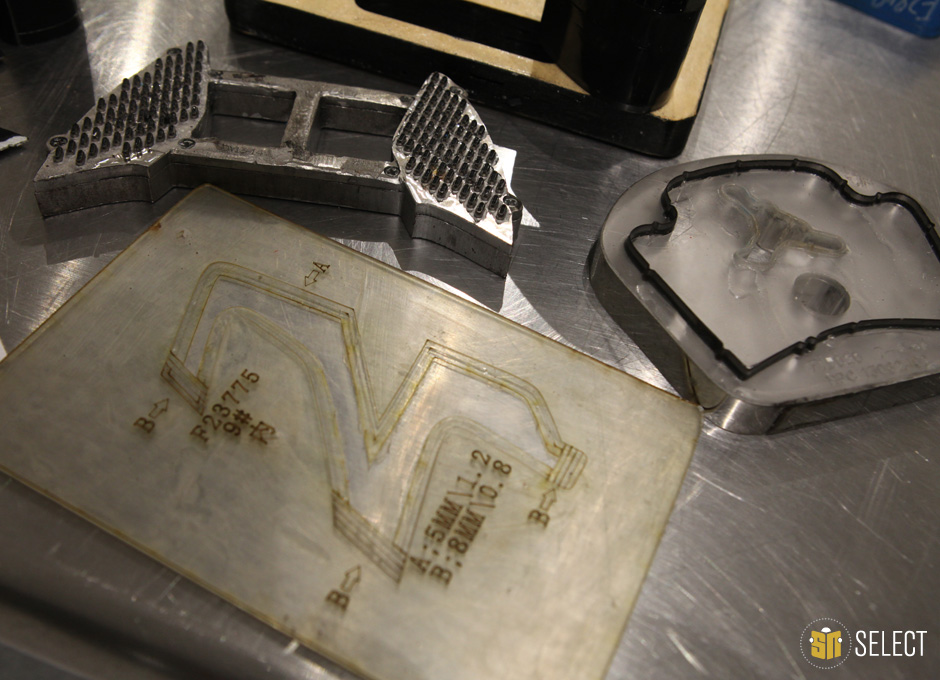

You don’t need to hold the Retro Remaster models in your hand to get a feel for the more premium grade of materials being used, but wait until you do. They provide us with the supple leather we’ve been longing for on our Retros with each panel of every shoe precisely color and texture-matched and analyzed for imperfections before being traced out and cut from large sheets of leather. Everything right down to the stitching threads used and the needles that sew them has been carefully considered not only to create a premium product, but to come as close as possible to replicating the models’ original constructions.

BUILT TO LAST

Aside from just the materials and construction, another key element of the Retro Remaster program will be an emphasis on durability. It’s painfully well-known to many of us that most sneaker models only have a certain lifespan before they start to break down from repeated wear (or not enough). Jordan Brand is on a mission to address some of the issues that have crumbled our soles in the past and ensure that the next generation of Retros surpasses the longevity of its predecessors.

ATTENTION TO DETAIL

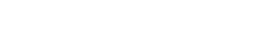

When it comes to getting the Retro Remasters as close to perfect as humanly possible, there are painstaking lengths taken to get things just right, both in design and production. Elaborate and innovative methods are employed to cut perfect edges on material panels, ensure precise perforation punctures, and remove excess glue and blemishes. Every little detail is being addressed right down to a more crisply executed Jumpman logo with defined fingers and shoelaces.

A DYING ART

It was noted a few times by the JB team that the process being re-instated here is indeed a dying art. With all the advancements in production methods over the years, very few brands are still using such an elaborate and intimate approach to shoe-making. As a result, it was initially a challenge for Jordan Brand to even find factories still equipped with the skill sets needed to meet the high demands of the Retro Remaster undertaking.

THE FIRST BATCH

As mentioned, the Remaster concept is not aimed to be some special new series or collection – it’s here to stay. All Air Jordan Retros will be made this way from now on starting with the seven makeups that have been unveiled. There will be three colorways of the IV: Columbia, Oreo, and a pair that takes the Green Glow theme in a new direction. There will also be three versions of the X: the classic “Double Nickel” and two NYC-themed pairs dubbed the “Bulls Over Broadway” and “Lady Liberty”. Last but not least is the return of the “French Blue” VII, which appears to be lined up to help kick off 2015’s Year of the VII celebration.

MICHAEL’S FEEDBACK

MJ was on board with the Remaster concept from day 1, but the designers responsible for bringing it to life got the ultimate compliment when he first put on a pair of the remastered Air Jordan 1s. When they asked him how they compared to the originals, he said they actually felt better, noting that he used to have to wear two pairs of socks with the 1s because the shoe was so stiff at first.

PRICING

There were all sorts of moans and groans about the price hike that will come along with the Retro Remasters, but the same people have been begging for better quality materials on their Jordans for years now. You don’t have to be too business savvy to understand that higher grade leather costs Nike more money to source, so of course a more premium product is going to come at a cost on the retail end. The number here is somewhere in the neighborhood of 10-15% which will work out to be roughly an extra $20 per pair. Sure, you can say it’s a slippery slope to higher sneaker prices across the board, but that’s happening regardless.

THE AIR JORDAN LEGACY

One of the broader goals of the Remaster process will be to ensure that every time a kid puts a pair of Air Jordan Retros on their feet for the first time, they get that same magical feeling that those of us who were around for the OG days remember so fondly. While some of the shoes being revamped were designed 25-30 years ago, Jordan Brand is going into this aiming to keep that magic alive for a new generation and hoping to contribute no shortage of new classics to the hallowed Air Jordan archives moving forward.